COVNA HK60-Q-GT 2 Way High Pressure Electric Ball Valve

AC220 V 2 Way High Pressure Electric Ball Valve

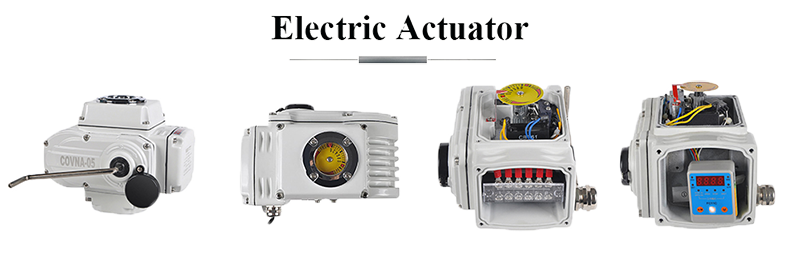

- Actuator Type: ON OFF Type, Regulating Type, and Intelligent Type

- Working Pressure Range: PN100~PN400

- Suitable Medium: Water, Oil, Air, Gas, etc

- Compact Design, Eco-friendly, Easy Installation, etc

- Voltage optional: 12V, 24V DC; 110V, 220V, 380V AC

- Widely used in HVAC, irrigation, water treatment, etc.

Types of High-Pressure Electric Ball Valve:

| ON/OFF Type | Feedback: the active contact signal, passive contact signal, resistance, 4-20mA |

| Regulation Type | Input & Output signal: DC 4-20mA, DC 0-10V, DC 1-5V |

| Field operation | The Field, Remote Control Switch Regulation and MODBUS, PROFIBUS Field Bus |

| Voltage Optional | AC110-240V 380V 50/60HZ: DC12V, DC24V, Special Voltage Can be Customized |

| Protection Class | IP65, Explosion Proof Construction Are Available: EX ll BT4 |

Technical Parameters of Valve Body

| Valve Body | Valve components | ||

| Nominal size | DN15-DN200 | Sealing material | PTFE: -20℃~180℃

PPL: -29℃~250℃ |

| Body Material | Stainless Steel | Disc Material | SS304, SS316, SS316L |

| End Connection | Thread | Stem Material | Stainless Steel |

| Operating Pressure | 1.0 / 1.6 / 2.0 / 6.4 MPa (10 / 16 / 20 / 64 bar) | Applicable media | Water, Air, Gas, Steam, Oil, Liquid |

| Structure | Floating ball core | Design standard | ISO, DIN, IDF, SMS, 3A |

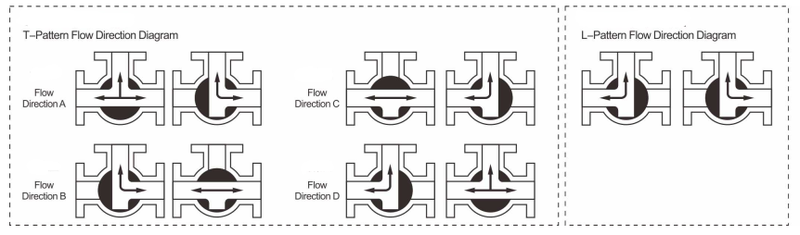

3 Way Ball Valve Flow Diagram:

● ON/OFF Type Electric Actuator: 90 degrees rotation. AC/DC power supply, signal control, and manual override. High torque up to 4000Nm.

● Modulating Type Electric Actuator: Adjust open/close angle from 0 to 90 degrees. AC/DC power supply, signal control, and manual override. High torque up to 4000Nm.

● Intelligent Type Electric Actuator: Adjust open/close angle from 0 to 90 degrees. LED display screen to allow you to check the open/close angle easier. AC/DC power supply, signal control, and manual override. High torque up to 4000Nm.

| Series | 5 | 10 | 16 | 30 | 60 | 125 | 250 | 400 |

| Torque Output | 50Nm | 100Nm | 160Nm | 300Nm | 600Nm | 1250Nm | 2500Nm | 4000Nm |

| 90° Cycle Time | 20S | 15/30S | 15/30S | 15/30S | 30S | 100S | 100S | 100S |

| Angle Of Rotation | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° |

| Working Current | 0.23A | 0.35A | 0.4A | 0.45A | 0.6A | 1.03A | 1.85A | 2.7A |

| Drive Motor | 50W | 75W | 80W | 100W | 130W | 210W | 285W | 360W |

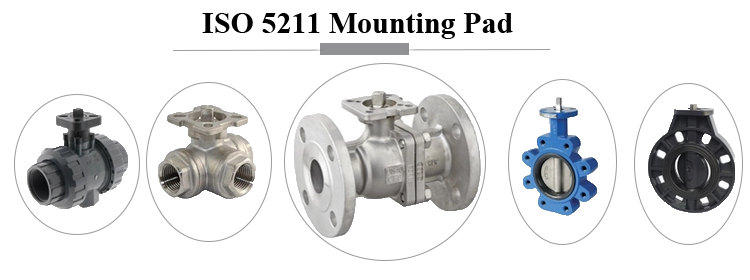

| Mounting Standard | ISO5211 direct mounting | |||||||

| Voltage Options | DC12V, DC24V, AC24V, AC110V, AC220V, AC380V | |||||||

| Input Signal | 4-20mA, 1-5VDC, 0-10VDC | |||||||

| Output Signal | 4-20mA, 1-5VDC, 0-10VDC | |||||||

| Protection Class | IP65 protection class | |||||||

| Ambient Temp | -20 to +60°C | |||||||

| Wiring Diagram | A: ON/OFF type with light indicator signal feedback | |||||||

| B: ON/OFF type with passive contact signal feedback | ||||||||

| C: ON/OFF type with resisance potentiometer signal feedback | ||||||||

| D: ON/OFF type with resistance potentiometer and neutral posistion signal feedback | ||||||||

| E: Regulation type with servo control module | ||||||||

| F: DC24/DC12V direct ON/OFF type | ||||||||

| G: AC380V 3-phase power supply with passive signal feedback | ||||||||

| H: AC380V 3-phase power supply with resistance potentiometer and neutral posistion signal feedback | ||||||||

Technical Parameter of Valve Body:

| Nominal Size | DN15-DN200 | Body Material | PVC, UPV, CPVC, PVDF and PPH |

| End Connection | True Union, Double Union Thread | Structure | T Port / L Port |

| Operating Pressure | 1.0 / 1.6 MPa (10 / 16 bar) | Voltage Tolerance | ±10% |

| Suitable Media | Corrosive media, Water, Air, etc | Temperature Of Media | -5~80℃ (23℉~176℉) |

| Design standard | ISO, DIN, IDF, SMS, 3A | Orifice(mm) | 15, 20, 25, 32, 40, 50, 65, 80, 100 |

Package & Shipping:

As a professional electric ball valve manufacturer, COVNA aims to provide our customers the best quality products with the most competitive pricing, on-time delivery and full warranty service with omprehensive service from start to finish, encompassing consultation through to after sales service, full support in every respect and ensure that you are accompanied at each stage of your project.

Company Profile:

_2022_03(1).png)

Factory Profile:

Company Certificates:

Purchase Guide:

● Confirm the valve size you need. We offer this High-Pressure Electric Ball Valve in 1/2in to 4in.

● Confirm the valve body material you need. We offer this High-Pressure Electric Ball Valve in stainless steel material.

● Confirm the connection standard. We offer this High-Pressure Electric Ball Valve in ANSI, JIS, DIN, and UK standard.

● Confirm the pressure and working temperature. Pressure and temperature are the important points and those may affect the cost.

● Confirm the voltage you need. The right voltage could help your valve operate better.

● Tell us your medium. Different medium has different features and we will help you to select the valve basic on the medium requirements

● Confirm the actuator type you need. We have on/off type, modulating type, intelligent type, explosion-proof type, IP68 type and auto return type electric valve actuator for your project.

Any requirements please tell us like core material, sealing material, or connection standard. We could help you to custom the valve you need.

More infomation, please send message to us. Quote will be provided within 2 hours! [email protected]

| Model | 5 | 10 | 16 | 30 | 60 | 125 | 250 | 400 |

| Torque Output | 50Nm | 100Nm | 160Nm | 300Nm | 600Nm | 1250Nm | 2500Nm | 4000Nm |

| 90°Cycle Time | 20s/60s | 15s/30s/60s | 15s/30s | 15s/30s | 30s/60s | 100s | 100s | 100s |

| Angle of Rotation | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° | 0-90° |

| Working Current | 0.25A | 0.48A | 0.68A | 0.8A | 1.2A | 2A | 2A | 2.7A |

| Starting Current | 0.25A | 0.48A | 0.72A | 0.86A | 1.38A | 2.3A | 2.3A | 3A |

| Drive Motor | 10W/F | 25W/F | 30W/F | 40W/F | 90W/F | 100W/F | 120W/F | 140W/F |

| Product Weight | 3kg | 5kg | 5.5kg | 8kg | 8.5kg | 15kg | 15.5kg | 16kg |

| Voltage Option | AC 110V, AC 220V, AC 380V, DC 12V, DC 24V | |||||||

| Insulation Resistance | DC24V:100MΩ/250V; AC110/220V/380V: 100MΩ/500V | |||||||

| Withstand Voltage | DC24V:500V; AC110/220V:1500V; AC380V:1800V 1Minute | |||||||

| Protection Class | IP65 | |||||||

| Installation Angle | Any | |||||||

| Electrical Connection | G1/2 Water-proof Gable Connectors, Electric Power Wire, Signal Wire | |||||||

| Ambient Temp. | -30℃to 60℃ | |||||||

|

Control Circuit

|

A: ON/OFF type with light indicator signal feedback | |||||||

| B: ON/OFF type with passive contact signal feedback | ||||||||

| C: ON/OFF type with resistance potentiometer signal feedback | ||||||||

| D: ON/OFF type with resistance potentiometer and neutral position signal feedback | ||||||||

| E: Regulation type with servo control module | ||||||||

| F: DC24V/DC12V dirct ON/OFF type | ||||||||

| G: AC380V three-phase power supply with passive signal feedback | ||||||||

| H: AC380V three-phase power supply with resistance potentiometer signal feedback | ||||||||

| Optional Function | Over Torque protectors, dehumidify heater, stainless steel coupling & yoke | |||||||

3D Display of Electric Valve:

● Before installing the valve, clean the line of dirt, scale, welding chips, and other foreign material Clean gasket surfaces thoroughly to insure leak-proof joints.

● Verify that the valve breakaway torque is less than the rated output torque of the actuator.

● Any mechanical stops that would interfere with the operation of the actuator must be removed before installation of the actuator, i.e. lever, travel stops, etc.

● The actuator output coupling must be centered with the valve stem to prevent side loading, which causes premature stem packing wear.

● To use the manual override feature (identified on cover label), the override shaft must be pressed down firmly at least 1/4" in order to disengage the motor from the gears. The manual override is not designed to overcome torque in excess of the rated torque of the actuator. Serious damage to the gear system may result from excessive turning force on the manual override.

● This Series actuator may be mounted in any position, i.e. horizontal, upside down. If the conduit entrance points upward, conduit piping must be oriented as to prevent condensation from enteringthe actuator from the conduit pipe.

Installation environment:

● The product can be installed indoor and outdoor, The surrounding environment temperature should be in -30°C~+60°C

● Product is non-explosion-proof production, and the installation must be avoided being in flammable or explosive environment etc.

● The actuator should be in protection box in the environment of long-term with the splash of rain, material and direct sunlight.

● Please reserve space for controller, manual operation.

★ The surrounding environment temperature should be in -30°C~+60°C.

Installed on the valve body:

● Manually operate the actuator to drive the valve, confirm it does not have abnormal situation. Turn the valve in full closed position.

● Assemble the bracket to the valve body.

● Set one end of couplings on valve spindle.

● Turn the electric actuator to full closing position, and insert output-input shaft into the square holes of couplings.

● Set the screw between the electric actuator and bracket.

● Turn actuator by hand shank, confirm that it moves translation, no eccentric, no skew and no overrun.

Cable installation:

● Install wire tubes, The outside diameter of wire tubes should be $9-411. Take measures to proof water. To prevent actuator from flowing into wire tubes water, the actuation position should higher than wire tubes position.

● When installing wire, the outside diameter of wire should be $9-φ11. in case the water flow into actuator interior from line locking, all wire that are not allowed to be used.

● The signal wire should be shielded wire in principle, don't parallel it to power wire.

Special tips:

● Caution: can't connect one actuator parallel with one another, in other words, can't use the same controller contact point to control more than one actuator, otherwise it will cause out of control, motor overheating, product damage, shorter service life.

● If the actuator is installed outdoor, we suggest equipping other protective cover to proof water, stabilize mechanical property, make a longer service life.

.jpg?imageView2/1/format/webp)